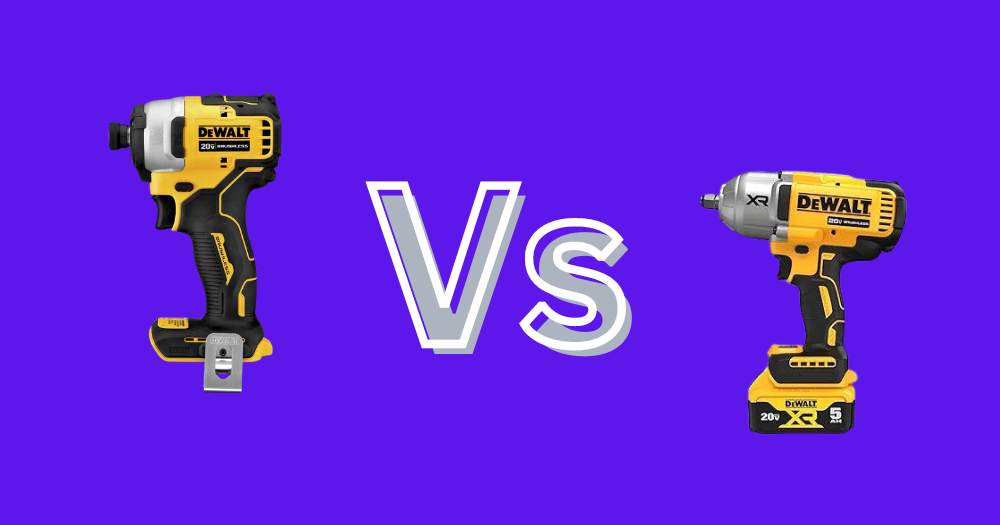

Are you confused about whether to use an impact driver vs drill for your next project? You’re not alone.

Both tools look similar but work very differently, and choosing the right one can make your job easier and faster. You’ll discover the key differences that matter, helping you pick the perfect tool for your needs. Keep reading, and you’ll never have to wonder which one to grab again.

Impact Driver Basics

An impact driver is a power tool used for driving screws and bolts. It is different from a drill because it uses both rotation and concussive force.

This tool helps to tighten screws quickly and with less effort. It is popular among builders and DIY enthusiasts.

How Impact Drivers Work

Impact drivers spin like drills but add strong bursts of force. These bursts increase torque without extra effort from the user.

The tool has a spring, hammer, and anvil inside. When resistance is met, the hammer hits the anvil, creating impacts.

- Motor spins the driver bit rapidly

- Spring compresses as resistance rises

- Hammer strikes the anvil to add impact

- Force helps drive screws into tough materials

Common Uses For Impact Drivers

Impact drivers are great for tasks requiring strong driving power. They work well with long screws and hard materials.

People use them for building decks, framing houses, and assembling furniture. They save time and reduce hand strain.

- Driving long screws into wood or metal

- Installing deck boards and fencing

- Assembling heavy furniture

- Working with tough materials like hardwood

Key Features Of Impact Drivers

Impact drivers have features that make them unique from drills. These features improve their power and ease of use.

Most impact drivers are compact, lightweight, and have quick-change chucks. They provide high torque and reduce bit slipping.

- High torque for tough fastening

- Compact size for tight spaces

- Quick-release chuck for easy bit changes

- Reduced vibration for user comfort

- Brushless motors for longer tool life (in some models)

Drill Fundamentals

Drills are common tools in homes and workshops. They help make holes and drive screws easily.

Understanding how drills work will help you choose the right tool for your project.

How Drills Operate

Drills use a motor to spin a bit at high speed. The bit cuts or drives into materials.

A trigger controls the speed. Pressing it harder makes the bit spin faster.

Typical Applications For Drills

Drills are used to make holes in wood, metal, plastic, and walls. They also drive screws.

They work well for furniture assembly, home repairs, and light construction tasks.

- Drilling holes for shelves or hooks

- Driving screws into wood or drywall

- Mixing paint or other liquids with special attachments

- Light sanding or polishing with attachments

Main Features Of Drills

Most drills have adjustable speed and torque settings. This helps match the tool to the task.

They often include a keyless chuck to change bits quickly and easily.

- Variable speed trigger for control

- Adjustable torque to prevent overdriving screws

- Keyless chuck for fast bit changes

- Forward and reverse rotation

- Lightweight and easy to handle

Power And Performance

Impact drivers and drills are common tools for many tasks. They look similar but work differently. Power and performance are key differences.

Understanding how each tool works helps you pick the right one for your job. Let’s compare their torque, speed, and handling of tough materials.

Torque Comparison

Torque measures how much turning force a tool has. Impact drivers provide more torque than drills. This helps with driving large screws and bolts.

Drills have lower torque but offer better control for delicate tasks. They work well for drilling holes and light fastening jobs.

- Impact drivers: High torque for tough fastening

- Drills: Moderate torque for versatile use

Speed Variations

Speed affects how fast a tool spins. Drills usually offer adjustable speeds. This lets you control the rate for different materials.

Impact drivers spin fast but deliver bursts of power. Their speed varies less and focuses on short, strong impacts to drive screws quickly.

- Drills: Variable speed for precision

- Impact drivers: High speed with impact bursts

Handling Tough Materials

Impact drivers handle tough materials better. They use rapid impacts to push screws into hard wood or metal. This reduces tool strain.

Drills can struggle with very hard materials. They may slow down or stall without impact power. Drills work best on soft to medium materials.

- Impact drivers: Ideal for hard wood and metal

- Drills: Best for soft wood and plastic

Credit: medium.com

Design And Build

Impact drivers and drills look similar but have different designs. Their build suits different tasks.

Understanding their design helps you pick the right tool for your work.

Size And Weight Differences

Impact drivers are usually smaller and lighter than drills. This size difference helps in tight spaces.

Drills tend to be bulkier because they have larger motors and chucks.

- Impact drivers weigh about 2 to 3 pounds

- Drills weigh about 3 to 5 pounds

- Smaller size makes impact drivers easier to handle

Chuck Types And Bit Compatibility

Drills use a keyless chuck that holds round and hex bits. This chuck fits many bit sizes.

Impact drivers use a quick-release hex chuck. They work best with hex-shank bits.

- Drills accept bits from 1/16 to 1/2 inch

- Impact drivers fit 1/4 inch hex bits only

- Impact drivers use bits made for high torque

Ergonomics And Grip

Impact drivers have a compact design with rubber grips for better control. They reduce hand strain.

Drills have a larger handle and often a side handle for extra stability during use.

- Impact drivers fit well in small hands

- Drills offer better grip for heavy drilling

- Rubber grips improve comfort on both tools

Usage Scenarios

Impact drivers and drills are useful tools for different tasks. Each tool works best in certain situations. Knowing their uses helps you pick the right one.

This guide explains when to use an impact driver or a drill. It covers the best tasks for each and how to choose between them.

Best Tasks For Impact Drivers

Impact drivers work well for driving screws and bolts. They deliver strong, quick bursts of power. This helps with tough fastening jobs.

They are great for tasks that need high torque without stripping screws. Impact drivers handle long screws and hard materials easily.

- Installing deck boards

- Building wooden fences

- Assembling metal frames

- Driving lag bolts

- Fastening drywall screws

Ideal Jobs For Drills

Drills work best for making holes in wood, metal, or plastic. They have adjustable speed and torque for different materials.

Drills can also drive screws but are less powerful than impact drivers. They are good for light to medium fastening tasks.

- Drilling pilot holes

- Installing shelves

- Hanging pictures or cabinets

- Building furniture

- Light screwdriving tasks

When To Choose One Over The Other

Choose an impact driver for strong, fast screwdriving jobs. It works well on tough materials and long screws.

Pick a drill when you need to make holes or work on delicate materials. It offers better control and speed settings.

- Use impact driver for heavy fastening

- Use drill for precise drilling tasks

- Impact driver is better for repetitive screwdriving

- Drill is preferred for versatility and hole making

Credit: www.youtube.com

Cost And Maintenance

Impact drivers and drills are common tools for construction and home projects. Both have different costs and maintenance needs. Knowing these differences helps you pick the right tool for your work and budget.

This section explains price ranges, battery life, charging, upkeep, and durability of impact drivers and drills.

Price Range Comparison

Impact drivers usually cost more than drills. This is because they have stronger motors and special features for heavy tasks.

Drills are simpler and often cheaper. They work well for light tasks like drilling holes and screwing.

- Impact Drivers: $80 to $200

- Drills: $50 to $150

- Higher price means better power and durability

Battery Life And Charging

Both tools mostly use lithium-ion batteries. Battery life depends on the battery size and tool use.

Impact drivers drain batteries faster because they use more power for tough jobs. Drills use less power, so batteries last longer per charge.

- Impact Drivers: shorter battery life, faster charging needed

- Drills: longer battery life, good for light jobs

- Charging time is about 30 minutes to 1 hour for both

Upkeep And Durability

Impact drivers have strong build parts to handle heavy use. They need regular cleaning and occasional lubrication.

Drills are simpler and easier to maintain. They need less frequent care but must stay clean and dry to last long.

- Impact Drivers: check brushes, clean vents, lubricate gears

- Drills: clean chuck, keep battery contacts clean

- Store both tools in dry places to avoid damage

Accessories And Attachments

Impact drivers and drills use different accessories and attachments. These tools need bits and extensions to do many jobs. Understanding their accessories helps you pick the right tool.

Both tools can fit common bits, but some attachments work better with one than the other. This guide looks at common bits, special attachments, and ways to boost tool use.

Common Bits And Extensions

Drills and impact drivers share many bits like drill bits and screwdriver bits. Extensions help reach tight spaces or drive screws deep. Both tools often use quick-change chucks or hex chucks.

- Drill bits for wood, metal, and plastic

- Screwdriver bits with different heads (Phillips, flat, Torx)

- Socket adapters for nuts and bolts

- Bit extensions for extra reach

- Right-angle attachments for tight spots

Specialized Attachments

Impact drivers handle tougher attachments than drills. They work well with heavy-duty bits for driving large screws and bolts. Drills fit attachments for drilling holes, mixing paint, or sanding.

- Impact-rated driver bits for high torque

- Drill hole saws for cutting large holes

- Mixing paddles for paint or cement

- Sanding discs and polishing pads

- Wire brushes for cleaning metal surfaces

Versatility Enhancements

Attachments can improve tool use in many ways. Adapters turn drills into drivers or connect to power accessories. Impact drivers use impact-rated parts for longer life. Both tools fit accessories that expand their functions.

- Universal adapters for multiple bit types

- Flexible shafts for curved or hard-to-reach spots

- Clutch systems on drills to prevent overdriving

- Impact-rated accessories for durability

- Quick-change systems for fast bit swaps

Credit: tools.mighty-seven.com

Safety Tips

Using an impact driver or drill can be dangerous without the right safety steps. Both tools need careful handling to avoid accidents.

This guide shares safety tips to protect yourself while working with these power tools.

Proper Handling Techniques

Hold the tool firmly with both hands to keep control. Always keep your fingers away from the bit or driver.

Use the right bit for the job. Do not force the tool; let it work at its own speed.

- Check the tool before use for any damage.

- Keep a steady stance to avoid slips.

- Turn off and unplug when changing bits.

- Keep work area clean and well-lit.

Protective Gear Recommendations

Always wear safety glasses to protect your eyes from flying debris. Ear protection helps reduce noise damage during use.

Wear gloves to protect your hands from sharp objects and vibrations. Avoid loose clothing that can get caught in the tool.

- Safety glasses or goggles

- Ear plugs or earmuffs

- Work gloves

- Long sleeves and fitted clothing

- Dust mask if working in dusty areas

Avoiding Common Mistakes

Do not use the wrong tool for the job. An impact driver is for driving screws, while a drill is for making holes.

Never apply too much pressure or use the tool at the wrong speed. This can cause the tool to slip or break.

- Do not remove safety guards.

- Do not hold the tool near the bit when running.

- Do not use damaged or worn bits.

- Do not work in wet or slippery places.

- Keep bystanders away from your work area.

Frequently Asked Questions

What Is The Main Difference Between An Impact Driver And Drill?

An impact driver delivers high torque with rapid bursts, ideal for driving screws. A drill rotates steadily, perfect for drilling holes. Impact drivers handle tough fastening jobs, while drills offer versatility for drilling and light driving tasks.

Can I Use An Impact Driver For Drilling Holes?

Yes, but impact drivers are less precise for drilling. They excel at driving screws and fasteners. For clean and accurate holes, a drill is better suited. Impact drivers may cause bit damage if used frequently for drilling.

Which Tool Is Better For Heavy-duty Fastening?

Impact drivers are better for heavy-duty fastening. They provide higher torque and impact force. This makes driving long screws and bolts easier. Drills lack the impact mechanism, so they struggle with tough fasteners.

Are Drills More Versatile Than Impact Drivers?

Yes, drills are more versatile. They can drill holes, mix paint, and drive screws. Impact drivers mainly focus on driving screws and bolts. For general household tasks, a drill is often more useful.

Conclusion

Choosing between an impact driver and a drill depends on your needs. Impact drivers excel at driving screws quickly. Drills are versatile for both drilling holes and driving screws. Consider the material you’re working with. For heavy-duty tasks, impact drivers shine.

For precision and versatility, drills are ideal. Both tools have their place in your toolbox. Evaluate the project requirements carefully. This will help you make the right choice. Always match the tool to the task for best results. Understanding their differences ensures better performance.

Equip yourself with the right tool for your next project.

12 min read