Have you ever wondered how to get the most out of your rotary tool? Whether you’re fixing, crafting, or customizing, the right attachments can make all the difference.

But with so many options available, it’s easy to feel overwhelmed. This guide will show you exactly how to use rotary tool attachments to unlock new possibilities and take your projects to the next level. Keep reading, and you’ll discover simple tips that can save you time, improve your results, and boost your confidence every time you pick up your tool.

Rotary Tool Basics

A rotary tool is a small handheld power tool. It spins a bit at high speed to cut, grind, or polish.

You can use different attachments to do many jobs with one tool. It is useful for DIY projects and crafts.

Types Of Rotary Tools

Rotary tools come in various types based on power and speed. Some are corded, and others run on batteries.

Each type suits different tasks. Choose one that fits your project size and power needs.

- Corded rotary tools: use electricity, offer constant power

- Battery-powered rotary tools: portable and easy to carry

- Variable speed tools: let you control the spinning speed

- Heavy-duty rotary tools: made for tough jobs and long use

Common Uses

Rotary tools do many jobs around the house and workshop. Attachments change the tool’s function.

They work on wood, metal, plastic, glass, and more. You can cut, sand, carve, and polish materials.

- Cutting small shapes or trimming materials

- Sanding rough edges or surfaces

- Carving designs into wood or plastic

- Grinding metal to smooth or sharpen

- Polishing jewelry or small metal parts

- Cleaning rust or paint from surfaces

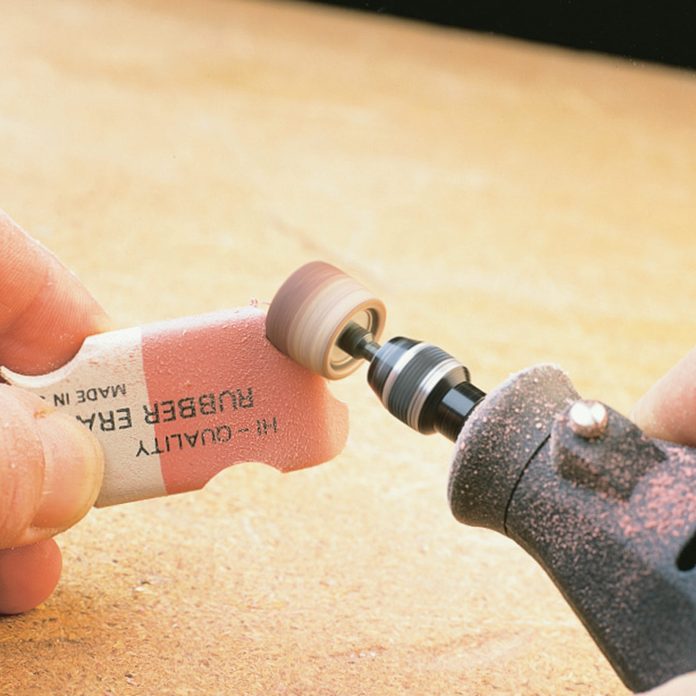

Credit: www.familyhandyman.com

Essential Attachments

Rotary tools are versatile machines used for many projects. Their power comes from different attachments.

Choosing the right attachment makes your work easier and more precise.

Cutting Wheels

Cutting wheels are thin discs that slice through materials. They work well on metal, plastic, and wood.

Use cutting wheels for small cuts and trimming tasks. They fit on most rotary tools easily.

Sanding Drums

Sanding drums help smooth rough surfaces. They come with sandpaper sleeves in different grits.

Attach sanding drums to remove paint or shape wood. Change sleeves as needed for fine or coarse sanding.

Grinding Stones

Grinding stones sharpen and shape hard materials. They are made of abrasive materials like aluminum oxide.

Use grinding stones on metal or glass to smooth edges or remove rust. Handle with care for safety.

Polishing Pads

Polishing pads clean and shine surfaces. They come in soft materials like felt or foam.

Attach polishing pads with polishing compounds to brighten metals or plastics. Use light pressure for best results.

Drill Bits

Drill bits make holes in various materials. They come in many sizes and types for wood, metal, or plastic.

Insert drill bits into the rotary tool chuck. Hold the tool steady to drill clean holes.

Choosing The Right Attachment

Rotary tools have many attachments for different tasks. Picking the right one helps you work better and safer.

Attachments fit specific materials and project needs. Choosing carefully saves time and effort.

Material Compatibility

Each attachment works best with certain materials. Using the wrong one can damage your work or tool.

Look at what your project needs and match the attachment to the material type.

- Cutting wheels are good for plastic, wood, and soft metals

- Sanding drums fit wood and plastic surfaces

- Grinding stones work well on metals and ceramics

- Polishing pads suit metals and plastics

Project Requirements

Think about the task before picking an attachment. Different jobs need different tools.

Choose attachments based on the shape, size, and finish you want to achieve.

- Use small drill bits for detailed work

- Pick large grinding stones for heavy material removal

- Choose fine sanding bands for smooth finishes

- Select polishing wheels for a shiny surface

Attaching And Detaching Accessories

Rotary tools use many attachments for different tasks. Knowing how to attach and detach them is important.

This guide shows safe and simple steps to change your rotary tool accessories.

Safety Precautions

Always unplug the rotary tool before changing accessories. This stops the tool from turning on by accident.

Wear safety glasses and gloves to protect your eyes and hands. Work in a clean, well-lit area.

- Unplug the tool before starting

- Wear safety glasses and gloves

- Keep your workspace clean and bright

- Check attachments for damage before use

- Do not force parts to fit

Step-by-step Process

First, loosen the collet nut by turning it counterclockwise. Use the wrench that came with your tool.

Remove the old attachment by pulling it out gently. Insert the new accessory into the collet.

Tighten the collet nut by turning it clockwise until it is snug. Do not overtighten, or the accessory may break.

- Unplug the tool

- Use wrench to loosen collet nut

- Remove old attachment

- Insert new accessory into collet

- Tighten collet nut securely

- Plug in and test at low speed

Speed Settings And Control

Rotary tools have different speed settings for many jobs. Choosing the right speed helps you work safely and well.

Knowing how to control speed makes your tool last longer. It also keeps your work neat and avoids damage.

Adjusting For Different Tasks

Different jobs need different speeds. Use low speed for delicate work and high speed for tough materials.

Check the tool’s manual to find the best speed for each attachment. Changing speed helps you get good results.

- Low speed for polishing and sanding

- Medium speed for grinding and cutting soft materials

- High speed for cutting or drilling hard materials

Avoiding Overheating

Running the tool too fast or too long can cause overheating. This can damage both the tool and the attachment.

Take breaks to cool the tool. Use the right speed and pressure to stop extra heat build-up.

- Use moderate speed for long jobs

- Let the tool rest every few minutes

- Do not press too hard on the attachment

- Keep vents clear for good air flow

Credit: www.familyhandyman.com

Safety Tips

Using rotary tool attachments can be helpful for many projects. Safety is very important to avoid accidents and injuries.

Follow these safety tips to protect yourself and work better with your rotary tool.

Protective Gear

Always wear protective gear when using rotary tools. This gear keeps you safe from dust, sparks, and sharp debris.

- Wear safety goggles to protect your eyes.

- Use gloves to protect your hands.

- Wear a dust mask to avoid breathing dust.

- Use ear protection if the tool is loud.

Workspace Setup

Set up your workspace to be clean and organized. A good workspace helps you work safely and avoid accidents.

- Work on a sturdy surface with good lighting.

- Keep the area free of clutter and flammable materials.

- Make sure the tool’s power cord is not in your way.

- Have a container to hold small parts and attachments.

Handling Techniques

Hold and use the rotary tool carefully. Proper handling helps you control the tool and avoid injuries.

- Hold the tool firmly but do not grip too tight.

- Keep your fingers away from the rotating parts.

- Use the correct attachment for your task.

- Do not force the tool; let it work at its own speed.

- Turn off and unplug the tool before changing attachments.

Maintenance And Care

Rotary tool attachments need regular care to last longer. Proper maintenance keeps them working well and safe.

Cleaning and storing attachments correctly stops damage and wear. This helps you get the best results every time.

Cleaning Attachments

Clean attachments after each use to remove dust and debris. This prevents build-up that can reduce their effectiveness.

Use a soft brush or cloth to clean the tools. Avoid using water on parts that may rust or get damaged.

- Brush off dust and dirt gently

- Use compressed air to remove small particles

- Wipe metal parts with a dry cloth

- Do not soak attachments in water

- Check for damage before storing

Storing Tools Properly

Store attachments in a clean, dry place to avoid rust and damage. Keep them organized to find them easily.

Use a case or container with compartments. This stops attachments from banging into each other and breaking.

- Keep tools in a dry environment

- Use storage boxes with separate slots

- Label compartments for quick access

- Avoid stacking heavy items on attachments

- Inspect tools before each use

Credit: www.amazon.in

Project Ideas For Beginners

Rotary tools are small machines with many attachments. They help you do many projects at home.

Using the right attachment makes your work easier and better. Here are some ideas for beginners.

Simple Cutting Projects

Cutting small items is easy with a rotary tool and a cutting wheel. You can cut plastic, wood, or metal.

Try making small crafts or fixing broken items by cutting parts to size.

- Cut plastic bottles for plant holders

- Trim wooden sticks for model building

- Cut metal sheets for custom shapes

Basic Sanding Tasks

Sanding attachments smooth rough surfaces. They work well on wood and metal.

Use sanding drums or discs to prepare surfaces for painting or finishing.

- Smooth edges of wooden toys

- Remove rust from metal tools

- Shape small craft pieces

Easy Polishing Jobs

Polishing attachments make surfaces shiny and clean. They work on metal, glass, and plastic.

Use polishing wheels or buffing pads with a polishing compound for best results.

- Polish old jewelry to restore shine

- Buff headlights for better light

- Clean and polish metal tools

Frequently Asked Questions

What Are The Main Types Of Rotary Tool Attachments?

Rotary tool attachments include grinding stones, sanding drums, cutting wheels, polishing pads, and drill bits. Each serves a unique purpose for cutting, shaping, polishing, or sanding materials efficiently.

How Do I Change Rotary Tool Attachments Safely?

To change attachments, first unplug the rotary tool. Use the included wrench to loosen the collet nut. Remove the old bit, insert the new attachment, and tighten securely before use.

Can Rotary Tool Attachments Work On Metal Surfaces?

Yes, many rotary tool attachments are designed for metal. Use cutting wheels for slicing metal and grinding stones for shaping. Always wear safety gear to protect against sparks and debris.

How Do I Maintain Rotary Tool Attachments For Longevity?

Clean attachments after each use to remove debris. Avoid overheating by using the tool at recommended speeds. Store attachments in a dry place to prevent rust and damage.

Conclusion

A rotary tool offers versatile uses with various attachments. Experiment with different attachments to find what works best. Always prioritize safety by wearing protective gear. Start with simple projects to build confidence. This approach helps improve skills gradually. Keep your tool clean and store it properly.

Proper maintenance ensures it lasts longer. Don’t hesitate to consult guides or tutorials. They can provide extra guidance and tips. Practice regularly to become more proficient. Soon, handling a rotary tool will feel natural. Enjoy the creativity and efficiency it brings to your projects.

10 min read