Are you ready to tackle your next woodworking or DIY project but unsure which saw to choose? Picking the right saw can make all the difference between a smooth cut and a frustrating mess.

Whether you’re cutting wood, metal, or even tile, each type of saw is designed for a specific purpose. Knowing which saw fits your needs will save you time, effort, and even money. Keep reading, and you’ll discover the key types of saws and how to use them like a pro—giving you the confidence to get your job done right every time.

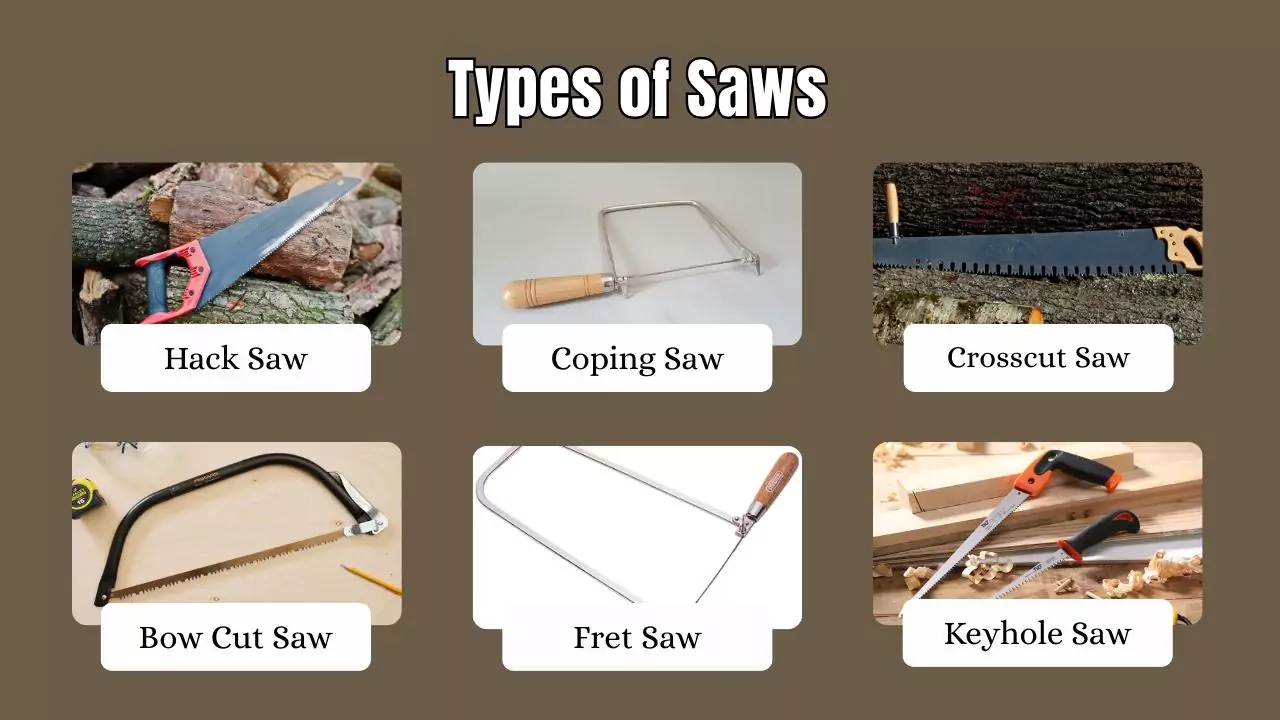

Hand Saws

Hand saws are simple tools used to cut wood and other materials. They do not need electricity.

There are many types of hand saws. Each one is made for a special job.

Crosscut Saw

The crosscut saw cuts across the grain of wood. It has small teeth that make smooth cuts.

This saw is good for cutting boards to length or trimming wood pieces.

Rip Saw

The rip saw cuts along the wood grain. It has bigger teeth than a crosscut saw.

This saw is used to split wood into smaller parts or cut boards lengthwise.

Back Saw

The back saw has a stiff metal spine on top. This helps keep straight cuts.

It is used for precise work like cutting joints and small wood parts.

Coping Saw

The coping saw has a thin, narrow blade held by a frame. It bends easily for curves.

This saw is good for cutting shapes and curves in wood or plastic.

Keyhole Saw

The keyhole saw has a long, thin blade with a pointed tip. It cuts small holes and tight spaces.

This saw is useful for cutting drywall, plaster, or small wood areas.

Credit: emiratesessential.com

Power Saws

Power saws are tools that use electricity to cut materials. They make cutting faster and easier than hand saws.

Different types of power saws fit different jobs. Each saw has a special design for certain cuts and materials.

Circular Saw

A circular saw has a round blade that spins quickly. It cuts straight lines through wood, metal, or plastic.

This saw is great for making long, straight cuts. It is portable and easy to use on large boards.

Jigsaw

A jigsaw has a small blade that moves up and down. It cuts curves and shapes in wood or metal.

This saw is good for detailed work and cutting patterns. It can also make straight cuts but is slower.

Reciprocating Saw

A reciprocating saw uses a blade that moves back and forth. It cuts wood, metal, and plastic quickly.

This saw is useful for demolition and cutting in tight spaces. It can cut through nails and pipes easily.

Miter Saw

A miter saw has a circular blade on a swing arm. It makes angled cuts for frames and moldings.

This saw is perfect for precise crosscuts and angled cuts. It helps create corners and joints in woodwork.

Table Saw

A table saw has a circular blade fixed under a flat table. The wood is pushed through the blade for cutting.

This saw is used for straight, long cuts and ripping wood. It is a common tool in workshops and carpentry.

Specialty Saws

Specialty saws are tools made for specific cutting jobs. They offer precision and power for unique tasks.

These saws help with materials that normal saws cannot handle well. They make difficult cuts easier and safer.

Band Saw

A band saw has a long, sharp blade shaped like a loop. It runs on wheels to cut wood, metal, or plastic.

This saw is good for making curved cuts and resawing thick wood into thinner pieces.

- Cuts straight and curved shapes

- Used for detailed woodworking

- Can cut metal with the right blade

- Ideal for resawing lumber

Tile Saw

Tile saws cut ceramic, porcelain, and stone tiles cleanly. They use a diamond blade to slice hard materials.

Water cools the blade to prevent overheating and dust. This saw is perfect for bathroom and kitchen projects.

- Diamond blade cuts hard tiles

- Water cooling reduces dust and heat

- Makes straight and angled cuts

- Used in tiling and flooring work

Chainsaw

A chainsaw has a motor and a chain with sharp teeth. It is great for cutting trees and large wood pieces fast.

This saw is used in logging, tree trimming, and clearing land. It works well outdoors on thick branches and trunks.

- Powerful and fast for big cuts

- Good for felling trees and trimming

- Uses a rotating chain with teeth

- Needs safety gear to operate

Scroll Saw

A scroll saw has a small, thin blade that moves up and down. It cuts detailed shapes and curves in wood or metal.

This saw is ideal for crafts, puzzles, and intricate patterns. It allows precise control for fine cutting work.

- Small blade for fine, detailed cuts

- Used in woodworking and crafts

- Good for curves and tight corners

- Works well on thin materials

Choosing The Right Saw

Choosing the right saw is important for any project. The right saw makes cutting easier and safer.

Different saws work best for different tasks. Understanding your needs helps you pick the right tool.

Project Requirements

Know what kind of cuts your project needs. Some saws cut straight lines, others cut curves or angles.

Think about how big or small your pieces will be. Also, check if you need smooth or rough cuts.

- Straight cuts: use a circular or table saw

- Curved cuts: use a jigsaw or coping saw

- Precise cuts: use a miter saw or handsaw

Material Types

Different materials need different saws. Wood, metal, and plastic require special blades and saws.

Using the right saw blade keeps your cuts clean and protects the material from damage.

- Wood: use a wood blade or handsaw

- Metal: use a metal-cutting blade or hacksaw

- Plastic: use a fine-tooth blade or jigsaw

Safety Considerations

Safety is key when using any saw. Always wear safety gear and follow instructions carefully.

Choose a saw with safety features like blade guards and easy-to-use switches.

- Wear safety glasses and gloves

- Keep your hands away from the blade

- Use saws with safety locks or guards

- Work in a clean, well-lit area

Saw Maintenance Tips

Keeping your saws in good condition helps them work better and last longer. Regular maintenance saves time and money.

Simple care steps can prevent damage and keep blades sharp. Follow these tips to maintain your saws properly.

Blade Care

Check your saw blades for damage before and after use. Avoid cutting materials that can harm the blade.

Use the right blade for the job to reduce wear. Replace blades if they are bent, cracked, or missing teeth.

Cleaning And Storage

Clean saw blades after each use to remove dirt and sap. Use a soft brush or cloth with mild cleaner for this task.

Store saws in dry places to stop rust. Keep blades covered or in cases to protect edges and avoid accidents.

- Remove debris and sticky residue

- Dry blades before storage

- Use blade guards or cases

- Keep saws in a dry, cool area

Sharpening Techniques

Sharp blades cut better and safer. Sharpen blades regularly to keep their edge strong.

Use a file or sharpening tool made for saw blades. Follow the blade’s original tooth shape and angle.

- Secure the blade before sharpening

- File each tooth evenly

- Keep the original angle of the teeth

- Check sharpness often

Credit: www.dreamstime.com

Credit: www.familyhandyman.com

Frequently Asked Questions

What Are The Main Types Of Saws Used In Woodworking?

The main types include handsaws, jigsaws, circular saws, miter saws, and table saws. Each serves specific cutting tasks, from rough cuts to precise angles.

How Do You Choose The Right Saw For A Project?

Consider the material, cut type, and precision needed. Handsaws suit small tasks, while power saws handle larger or complex cuts efficiently.

What Safety Tips Should I Follow When Using Saws?

Always wear protective gear, keep blades sharp, and use proper cutting techniques. Ensure the workpiece is secured to prevent accidents.

Can Saws Be Used For Cutting Materials Other Than Wood?

Yes, with appropriate blades, saws can cut metal, plastic, and drywall. Always select a blade designed for the specific material for best results.

Conclusion

Choosing the right saw improves your projects greatly. Each saw serves a specific purpose. Hand saws are great for small tasks. Power saws handle bigger jobs efficiently. Circular saws cut fast and precise. Jigsaws offer flexibility for curved cuts. Miter saws excel in making angled cuts.

Reciprocating saws help with demolitions. Knowing each saw’s function saves time and effort. Investing in the right tools leads to better results. Always prioritize safety while using saws. Equip yourself with knowledge and the correct saw. Your projects will shine with the right tools in hand.

8 min read