Are you staring at a stubborn bolt or nut, wondering, “What size wrench do I need?” Choosing the right wrench size can save you time, prevent damage, and make your job easier. But with so many sizes and types out there, it’s easy to get confused.

This guide will help you quickly find the perfect wrench for your task, so you can work smarter, not harder. Keep reading to unlock simple tips that will make every fix feel like a breeze.

Credit: www.reddit.com

Types Of Wrenches

Wrenches are tools used to turn nuts and bolts. They come in different types for many tasks.

Choosing the right wrench size helps you work safely and easily. Here are common wrench types.

Open-end Wrench

An open-end wrench has a U-shaped opening. It fits two opposite sides of a bolt or nut.

This wrench works well in tight spaces. You can slide it onto the fastener from the side.

- Comes in fixed sizes

- Good for quick adjustments

- Not ideal for rounded bolts

Box-end Wrench

A box-end wrench surrounds the bolt head fully. It has a closed loop that grips all sides.

This wrench reduces slipping and rounding. It offers more torque than an open-end wrench.

- Fits snugly on hexagonal bolts

- Good for tight bolts

- Can be offset for better access

Adjustable Wrench

An adjustable wrench has a movable jaw. You can change its size to fit different bolts.

This wrench is versatile and saves space. It is not as strong as fixed-size wrenches.

- Ideal for various bolt sizes

- Easy to carry one tool

- Jaw can slip if not tight

Socket Wrench

A socket wrench uses a ratchet handle. It holds a socket that fits over nuts and bolts.

This wrench is fast for tightening or loosening. Sockets come in many sizes for different bolts.

- Provides high torque

- Works well in tight spaces

- Requires a set of sockets

Combination Wrench

A combination wrench has an open end and a box end. Both ends fit the same bolt size.

This wrench offers flexibility in one tool. Use the open end for quick work and box end for strength.

- Two tools in one

- Good for many jobs

- Saves space in your toolbox

Measuring Wrench Size

Choosing the right wrench size is important for fixing nuts and bolts. A wrench that fits well prevents damage.

This guide explains how to measure wrench size correctly. It covers metric and imperial sizes, measuring nuts and bolts, and using size charts.

Metric Vs Imperial Sizes

Wrench sizes come in two main systems: metric and imperial. Metric uses millimeters. Imperial uses inches.

Metric wrenches fit nuts and bolts measured in millimeters. Imperial wrenches fit sizes in inches or fractions.

- Metric sizes are usually even numbers, like 10mm or 12mm.

- Imperial sizes can be fractions, like 1/2 inch or 3/4 inch.

- Always check which system your fastener uses before choosing a wrench.

Measuring Nut And Bolt

To find the right wrench size, measure the nut or bolt’s width across flats. This is the distance between two opposite sides.

Use a ruler or caliper to get an accurate measurement. Measure in millimeters for metric and inches for imperial.

- Place the tool across the nut or bolt flat sides.

- Note the measurement without including the rounded edges.

- Match this size to the wrench size to get a proper fit.

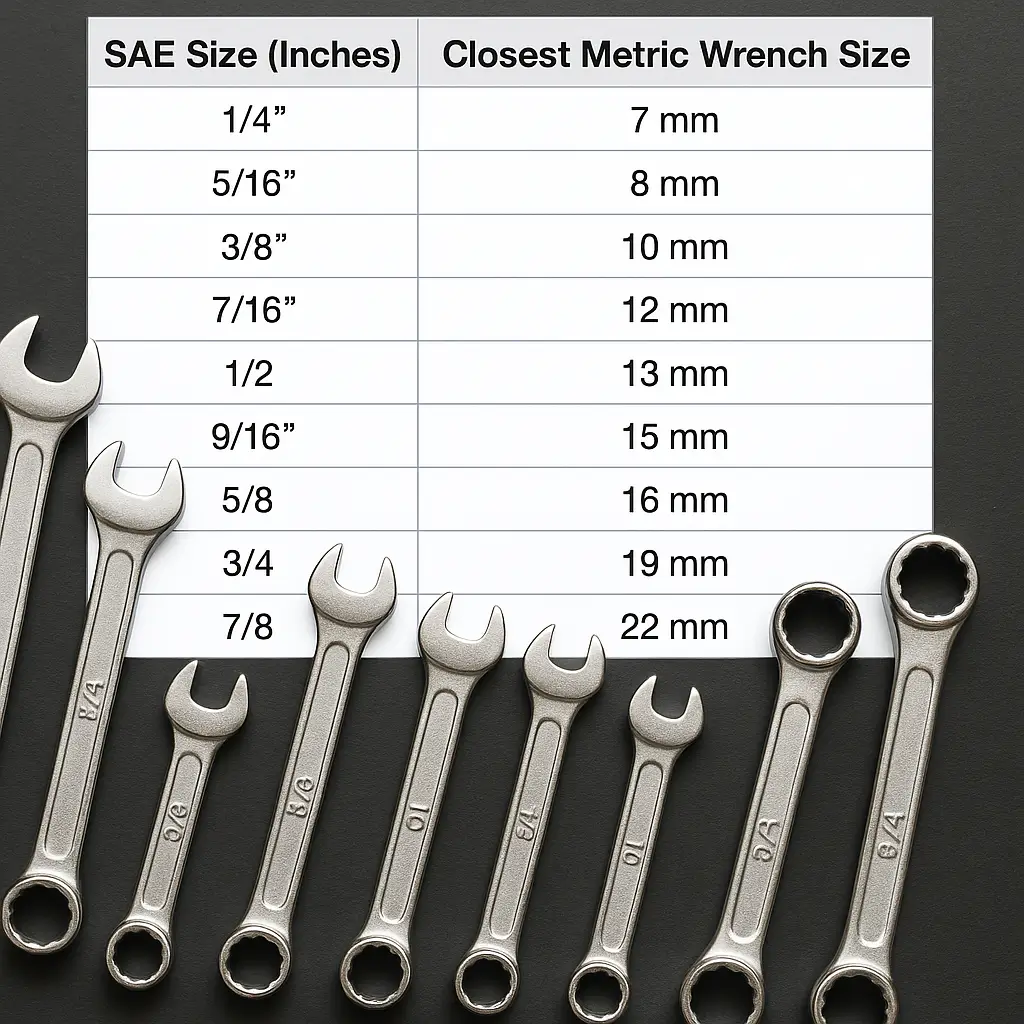

Using A Wrench Size Chart

A wrench size chart helps you find the correct wrench based on your nut or bolt measurement. It shows metric and imperial sizes side by side.

Charts list common wrench sizes and the corresponding nut or bolt widths. Use the chart to pick the wrench that fits your measurement.

| Nut/Bolt Width | Metric Wrench Size | Imperial Wrench Size |

|---|---|---|

| 10 mm | 10 mm | 3/8 inch |

| 13 mm | 13 mm | 1/2 inch |

| 17 mm | 17 mm | 11/16 inch |

| 19 mm | 19 mm | 3/4 inch |

Common Wrench Sizes For Household Jobs

Wrenches come in many sizes for different tasks. Using the right size helps you work faster and avoid damage.

This guide covers common wrench sizes you need for typical home jobs. It focuses on plumbing, furniture, and bike repairs.

Plumbing Repairs

Plumbing often needs adjustable and fixed wrenches. Common sizes fit nuts and bolts on pipes and fixtures.

Most household plumbing uses 10mm to 22mm wrench sizes. Adjustable wrenches also work well for odd sizes.

- 10mm for small pipe fittings

- 13mm for faucet nuts

- 17mm for shower head nuts

- 19mm to 22mm for larger pipe joints

Furniture Assembly

Furniture bolts vary but most use metric sizes from 8mm to 15mm. Allen wrenches are common too.

Having a set of wrenches in these sizes helps you tighten bolts without slipping or damage.

- 8mm for smaller bolts

- 10mm for medium bolts

- 13mm for larger bolts

- Allen wrenches for hex bolts

Bicycle Maintenance

Bikes use smaller wrench sizes mostly in millimeters. Common sizes fit nuts on wheels and brakes.

Some parts need cone wrenches, which are thin and fit tight spaces. A 15mm wrench is very common.

- 8mm for seat posts and accessories

- 10mm for brake bolts

- 15mm for wheel nuts

- Cone wrenches for hubs

Wrench Sizes For Automotive Work

Choosing the right wrench size is important for car repairs. Using the wrong size can damage bolts and nuts.

This guide helps you find the right wrench sizes for common automotive tasks. It covers engine parts, tires, and brakes.

Engine Components

Engine parts often use metric wrenches. Sizes like 10mm, 12mm, and 14mm are common for bolts.

Some larger bolts need 17mm or 19mm wrenches. Always check the size before starting work.

- 10mm – small bolts on sensors and covers

- 12mm – medium bolts on brackets and hoses

- 14mm – larger bolts on engine mounts

- 17mm and 19mm – heavy bolts on main engine parts

Tire And Wheel Nuts

Wheel nuts usually need larger wrenches. Common sizes are 19mm, 21mm, and 22mm.

Some trucks and SUVs use even bigger sizes like 24mm or 27mm. Use a breaker bar for tight nuts.

- 19mm – common on cars and small SUVs

- 21mm – used on many passenger vehicles

- 22mm – found on some trucks and SUVs

- 24mm and 27mm – for heavy-duty trucks

Brake System

Brake parts use medium-size wrenches. Sizes like 10mm, 12mm, and 14mm fit brake calipers and lines.

Always use the correct size to avoid stripping bolts on brake components. Safety is important here.

- 10mm – brake line fittings and small bolts

- 12mm – caliper bolts and brackets

- 14mm – larger caliper mounting bolts

Industrial And Heavy-duty Wrench Sizes

Heavy-duty wrenches come in many sizes. Choosing the right size helps you work safely and quickly.

This guide focuses on wrench sizes for industrial and large equipment tasks. Knowing the correct size is key.

Construction Equipment

Construction machines use big bolts and nuts. Wrenches for these parts are usually large and strong.

Common wrench sizes for construction tools range from 19 mm to 50 mm. Some parts may need even bigger sizes.

- Small bolts: 19 mm to 24 mm

- Medium bolts: 27 mm to 36 mm

- Large bolts: 41 mm to 50 mm+

Machinery Maintenance

Machinery needs regular checks and repairs. Wrenches for maintenance vary in size based on machine type.

Sizes from 13 mm to 46 mm cover most machinery bolts. Some heavy machines require special extra-large wrenches.

- Small bolts: 13 mm to 19 mm

- Standard bolts: 22 mm to 32 mm

- Heavy bolts: 36 mm to 46 mm

Large Bolts And Fasteners

Large bolts and fasteners need very big wrenches. These sizes often go beyond regular tool sets.

Wrenches for large fasteners usually start at 41 mm and can reach 75 mm or more. Heavy-duty jobs need these sizes.

| Wrench Size (mm) | Use Case |

|---|---|

| 41 – 50 | Heavy machinery bolts |

| 51 – 65 | Large industrial fasteners |

| 66 – 75+ | Special heavy-duty connections |

Tips For Choosing The Right Wrench

Choosing the right wrench size is important for any job. Using the correct size helps you work faster and safer.

Learn some simple tips to pick a wrench that fits well and lasts long. This will protect your tools and the parts you work on.

Fit And Comfort

Pick a wrench that fits the bolt or nut snugly. A good fit stops slipping and saves your hands from injury.

Comfort is key when using a wrench for a long time. Look for handles that are smooth and easy to grip.

- Use a wrench that matches the exact size of the fastener

- Check if the wrench grips tight without wiggle

- Choose handles with a soft or textured surface

- Make sure the wrench feels balanced and not heavy

Material And Durability

Strong materials make wrenches last longer. Look for wrenches made from steel or other tough metals.

A durable wrench resists rust and bending. This keeps it working well even after many uses.

- Choose wrenches made from chrome vanadium or alloy steel

- Look for corrosion-resistant finishes like chrome plating

- Avoid cheap metals that bend or break easily

- Check if the wrench feels solid and heavy enough

Avoiding Damage

Using the wrong wrench size can damage nuts and bolts. It can also harm the wrench itself.

Always measure the fastener before picking a wrench. Use adjustable wrenches carefully to avoid slipping.

- Match wrench size exactly to the fastener

- Do not force a wrench that is too small or too big

- Keep wrenches clean and well-maintained

- Use the right type of wrench for the job

Maintaining Your Wrenches

Wrenches are useful tools that last longer with proper care. Keeping them clean and in good shape helps you work safely and easily.

Learn simple ways to clean, store, lubricate, and check your wrenches. These steps save money and keep your tools ready.

Cleaning And Storage

After using wrenches, remove dirt and grease with a cloth. Clean tools work better and last longer.

Store wrenches in a dry place to stop rust. Use a toolbox or hang them on a rack.

- Wipe tools after each use

- Keep them away from moisture

- Organize by size for easy access

Lubrication

Lubricate moving parts of adjustable wrenches to keep them smooth. Use light oil for best results.

Apply oil lightly and wipe off extra. This stops parts from sticking or rusting.

- Use machine or WD-40 oil

- Oil the screw and sliding parts

- Do this regularly for smooth use

Inspection And Replacement

Check your wrenches often for cracks or worn jaws. Damaged tools can slip and cause injury.

Replace wrenches that are bent or broken. Using good tools keeps your work safe and easy.

- Look for cracks or rust spots

- Test adjustable parts for smoothness

- Throw away tools that do not work well

Credit: www.soartectools.com

Frequently Asked Questions

What Size Wrench Fits A 1/2 Inch Bolt?

A 1/2 inch bolt typically requires a 3/4 inch wrench. This size ensures a snug fit to avoid slipping. Always check the bolt head type and measure carefully for best results.

How To Measure Wrench Size For A Hex Bolt?

Measure the distance across the bolt’s flat sides with a caliper. This measurement equals the wrench size needed. Using the correct size avoids damage and ensures proper grip.

Can Adjustable Wrenches Replace Fixed-size Wrenches?

Yes, adjustable wrenches fit various sizes, offering flexibility. However, fixed-size wrenches provide better grip and torque. Use adjustable wrenches for convenience, but fixed ones for precision work.

Why Is Wrench Size Important For Bolt Tightening?

Correct wrench size prevents rounding or damaging bolt heads. It ensures proper torque application, maintaining joint integrity. Using the wrong size can lead to tool slippage and injury.

Conclusion

Choosing the right wrench size is crucial for your projects. It ensures tasks are done safely and efficiently. Always check the size of the bolt or nut first. Use a reliable wrench size chart for guidance. Keep a set of wrenches for different needs.

This way, you’re ready for any job. Proper tools can save time and effort. Practice using them to get comfortable. With patience, you’ll become more confident in your choices. Remember, having the right size wrench makes work easier and more enjoyable.

10 min read